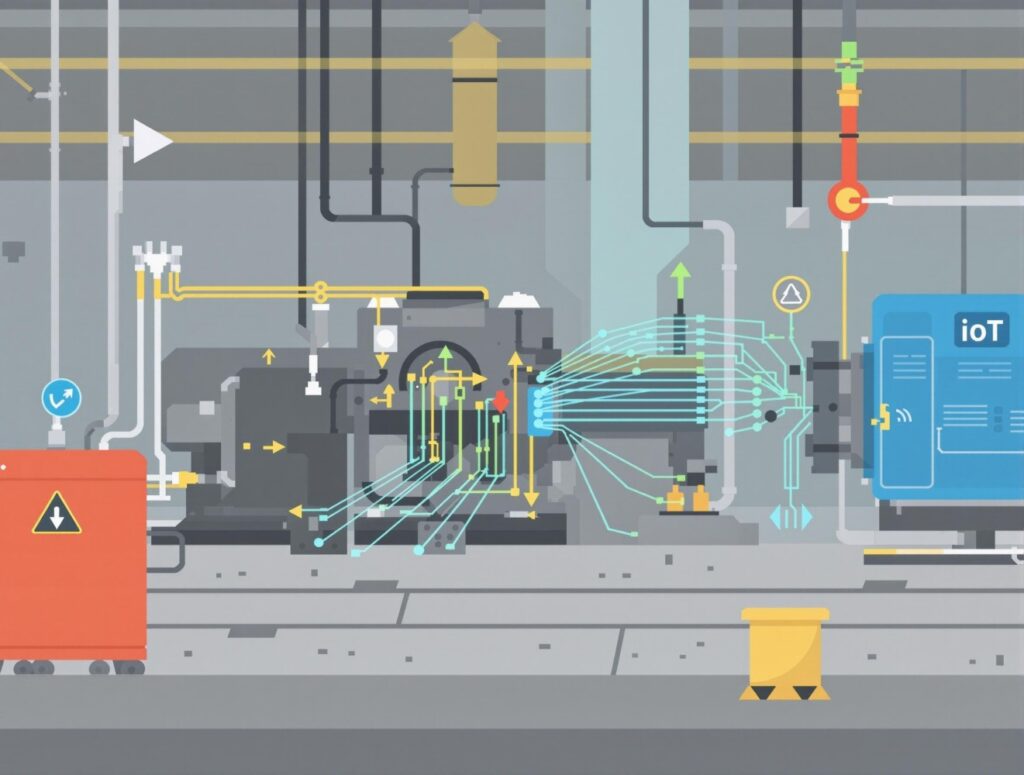

In modern industry, the integration of IoT technology with vibration sensorsis transforming how companies manage and maintain their equipment.

By providing real-time insights into machine performance and condition, these systems allow businesses to optimize maintenance schedules, minimize downtime, and extend the lifespan of their machinery.

Bariga IT Solutions has developed advanced IoT solutions tailored to machine monitoring, ensuring operational efficiency and cost-effectiveness.

Traditional machine maintenance practices often lead to inefficiencies that can disrupt operations and increase costs:

– Late Detection of Issues: Problems are usually identified only after significant damage or breakdowns occur, resulting in unplanned downtime and expensive repairs.

– Rigid Maintenance Schedules: Maintenance is often performed on a fixed schedule, regardless of the actual condition of the equipment, leading to unnecessary servicing or missed issues.

– High Costs and Reduced Productivity: Emergency repairs and frequent downtimes disrupt production schedules, increasing operational costs and reducing efficiency.

– Lack of Real-Time Data: Without continuous monitoring, businesses rely on reactive rather than proactive decision-making.

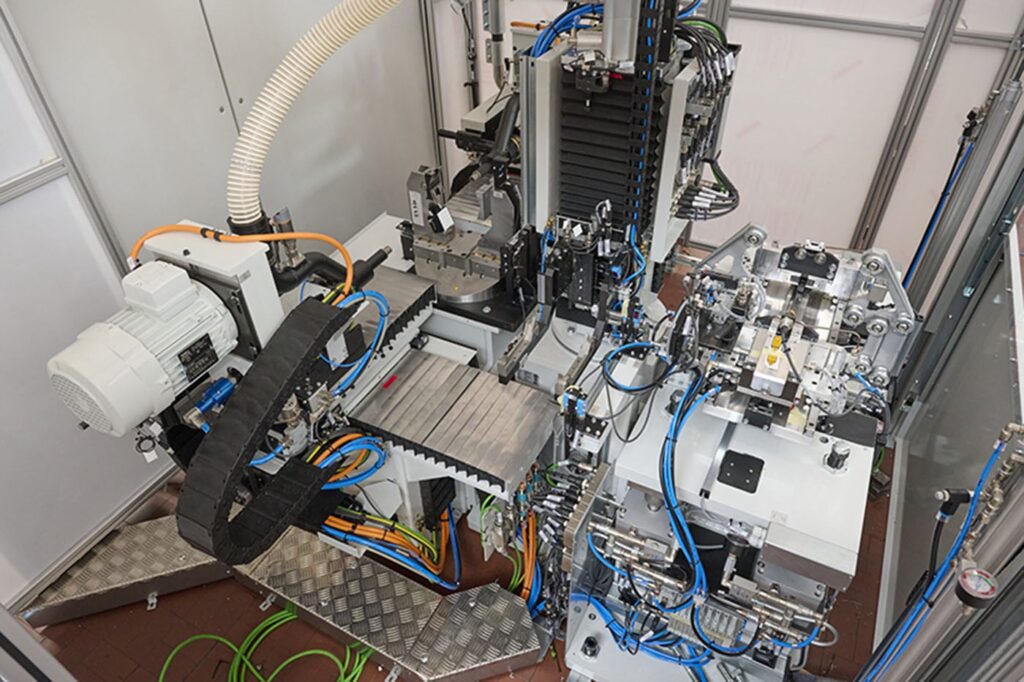

Bariga IT Solutions introduced a cutting-edge IoT-based machine monitoring system using advanced vibration sensors. These solutions provide real-time data, enabling proactive maintenance and operational optimization.

Vibration sensors continuously monitor machine performance, detecting unusual patterns or deviations. For instance:

– Learning Vibration Patterns: Sensors adapt to the unique vibration patterns of a machine during an initial learning phase. Any anomaly triggers an immediate alert, allowing for timely intervention.

– Reliable Standards-Based Monitoring: Sensors evaluate vibrations according to international standards, ensuring reliable early detection of potential issues in rotating machinery such as pumps and motors.

Bariga’s IoT solutions enable maintenance planning based on actual equipment conditions rather than fixed schedules. Benefits include:

– Efficient Servicing: Maintenance can be performed during non-production hours, reducing disruptions.

– Cost Savings: Maintenance cycles are optimized, avoiding unnecessary interventions and minimizing repair costs.

– Extended Machine Lifespan: Machines are maintained in optimal condition, prolonging their operational life.

By minimizing unplanned downtimes and optimizing machine performance, businesses can achieve:

– Higher Efficiency: Minimizing unplanned downtimes boosts production output.

– Reduced Costs: Emergency repairs and operational inefficiencies are significantly reduced.

– Improved Resource Allocation: Real-time insights enable better planning and resource management.

Bariga IT Solutions employs advanced vibration sensors with the following capabilities:

– Sensors adapt to the specific vibration patterns of each machine during an initial learning phase.

– Multiple operating modes can be learned and recognized for machines with varying performance states.

– In addition to vibrations, sensors measure environmental factors such as temperature, humidity, and pressure, providing comprehensive insights into machine health.

– Designed for use in hazardous environments, sensors ensure safe operation by preventing sparks or high temperatures.

– Sensors conserve energy by sending periodic reports only when no anomalies are detected, reducing data transmission frequency.

Bariga IT Solutions’ IoT vibration sensor solutions have delivered measurable benefits to clients across various industries:

1. Reduced Downtime: Unplanned machine downtimes were reduced by 40%, ensuring uninterrupted operations.

2. Cost Optimization: Maintenance costs decreased by 30% due to targeted, condition-based servicing.

3. Improved Safety: Early anomaly detection enhanced workplace safety and prevented catastrophic failures.

4. Scalability: The IoT network’s low-threshold setup enabled monitoring across multiple sites with minimal effort.

IoT-enabled machine monitoring with vibration sensors is revolutionizing industrial maintenance. Bariga IT Solutions provides tailored solutions that empower businesses to transition from reactive to proactive maintenance strategies, enhancing efficiency and reducing costs.

Are you ready to modernize your maintenance processes and maximize operational efficiency?

Contact Bariga IT Solutions today to explore how our IoT solutions can transform your operations and drive sustainable growth. Together, we can build a smarter, more sustainable future for your business.

Tell us what you need and schedule a call

info@barigaitsolutions.com

Tel.: +39 334 9268203

VAT: IT01603280296

© 2025 Created by BARIGA IT SOLUTIONS