How Robotics, AI, and IoT Are Revolutionizing Construction Site Safety in Italy

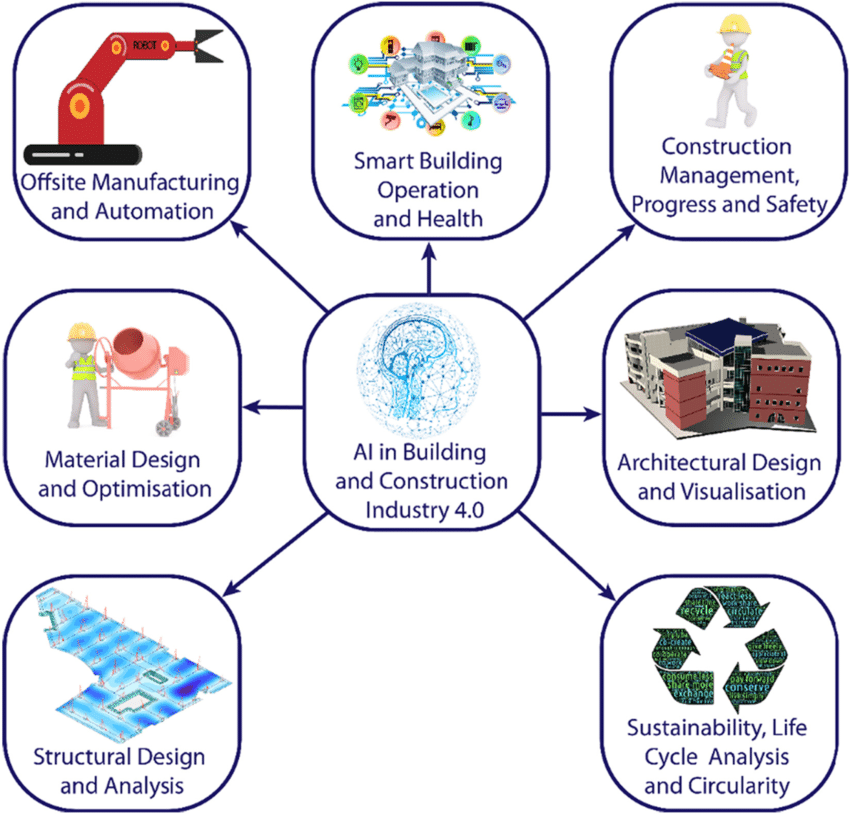

The construction sector in Italy, historically burdened by high accident rates, is undergoing a radical transformation thanks to the integration of robotics, artificial intelligence (AI), big data, and IoT (Internet of Things).

In 2024, over 593,000 workplace injuries were reported to INAIL, with the construction sector recording 182 fatal cases—remaining among the most hazardous industries despite a slight decrease from the previous year. These numbers underscore the urgency for innovative solutions.

Recent Data: The State of Construction Safety in Italy

- According to INAIL, while reported accidents among workers decreased by 1% in 2024, fatal accidents in construction remain alarmingly high, with more than three deaths per day across all sectors.

- Italy has invested over €4.1 billion in workplace safety projects since 2010, with €600 million allocated in 2024—the highest ever—for prevention and technological innovation.

- Despite these investments, the sector continues to grapple with recurring hazards: falls from heights, machinery collisions, and exposure to dangerous substances.

Technological Innovations Shaping Safer Sites

The 2025 BIT (Bando Innovazione Tecnologica) competition, promoted by INAIL and Artes 4.0, has spotlighted projects that use robotics, AI, and IoT to proactively prevent accidents. Here are the key innovations:

- Robotics: Autonomous robots and drones are deployed for hazardous inspections and material handling, reducing human exposure to risk. In Italy, the “Concert” robot prototype is being tested to assist workers in high-risk environments.

- AI & Predictive Analytics: AI-driven systems analyze real-time site data, flagging unsafe behaviors and environmental anomalies before they escalate. These tools enable predictive, rather than reactive, safety management.

- IoT & Wearables: Smart helmets, vests, and wristbands monitor workers’ positions, vital signs, and fatigue, sending instant alerts in case of danger. Environmental sensors detect toxic gases, extreme temperatures, and equipment malfunctions.

- Digital Twins: Virtual models of worksites simulate safety scenarios, test emergency response strategies, and optimize evacuation plans, allowing companies to identify and mitigate risks in advance.

Impact and Industry Trends

- The global market for AI in construction is projected to reach $12.1 billion by 2030, with Italy playing a leading role in Europe’s digitalization of safety protocols.

- 87% of industry professionals agree that robotics and automation improve both productivity and safety, according to recent surveys.

- Wearable tech and automated guided vehicles (AGVs) are now widespread on Italian sites, reducing injuries from lifting, fatigue, and collisions.

Challenges and Future Outlook

While the potential of these technologies is immense, successful adoption depends on workforce training, system interoperability, and robust data governance. Legal and ethical challenges—such as liability for AI-driven errors and data privacy—are also emerging as automation becomes central to compliance frameworks.

Despite these hurdles, the trajectory is clear: Italy’s construction sector is shifting from manual, reactive safety to a proactive, tech-driven culture. The ultimate goal is zero accidents—a vision now within reach thanks to digital transformation.

Find the best IT partner for your needs.

Tell us what you need and schedule a call